Stocking Hospital Supply Rooms (Two-Bin Kanban)

Summary

Stockouts and overstocking are common in hospitals. This is because either (a) no inventory system is used or (b) the PAR system is used - and to determine hospital inventory, every item in the hospital must be counted.

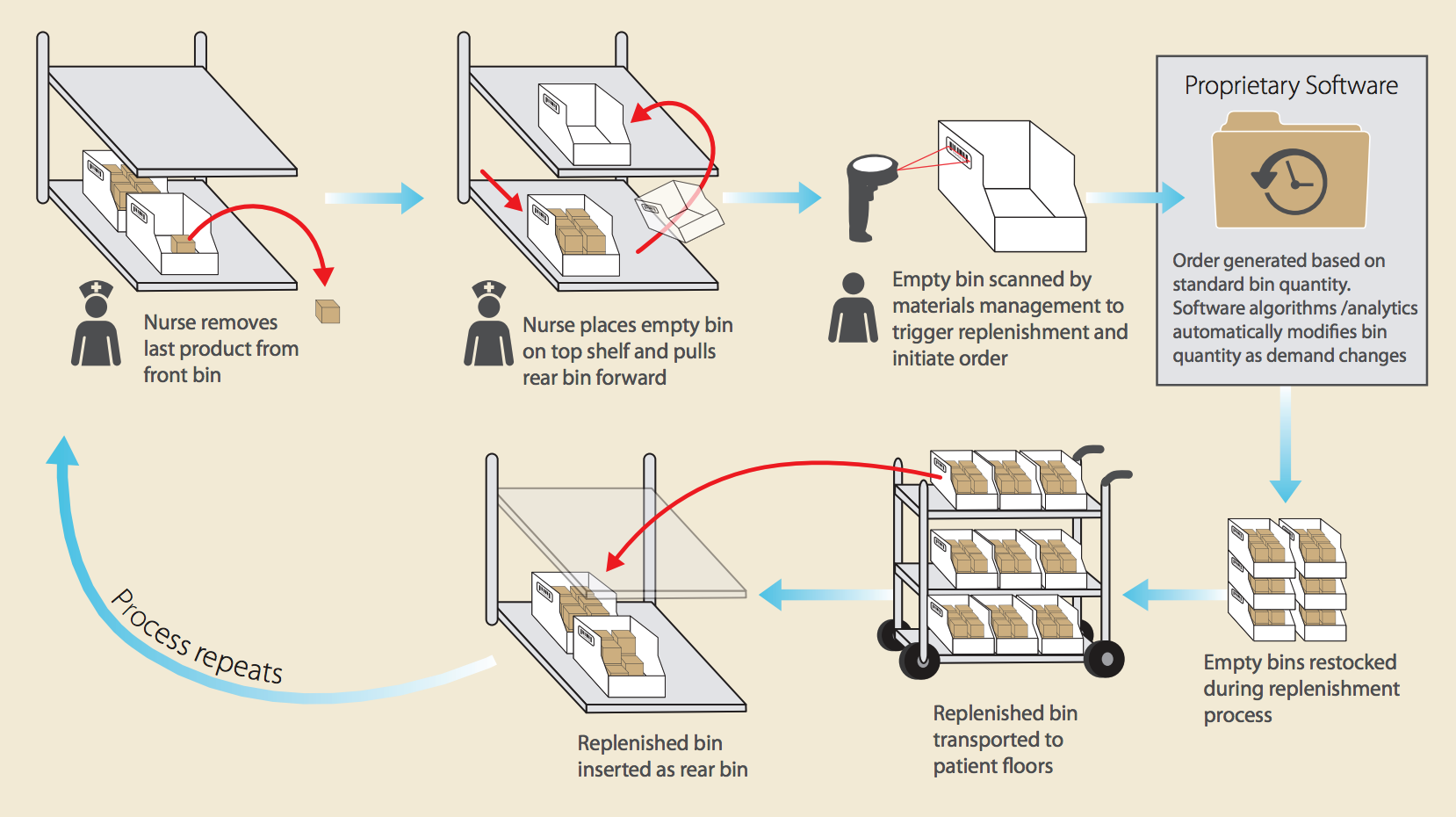

A much better system is kanban. It can speed up the time to find and stock items. Two-bin kanban involves two bins with identical quantities. Bins are placed front-to-back. Items are picked from the first bin, and when empty it is placed on the top shelf to be refilled. The second bin is pulled forward to the position of the first, and stock is pulled from it. When the first bin is restocked it is placed where the second bin originally was. The bins rotate in this manner, never running out, and easily alerting staff when refill is required.

Summary Video: How St Clair moved from PAR system to Kanban

Introduction

If grocery stores stocked their shelves with the same reliability as hospital supply rooms, certain isles would be overflowing, and others sparse. Each store in the chain would have a different layout. You would never know if what you were looking for was either out of stock, misplaced, or not carried. Items in the store would turn over at different rates, with some gathering dust and expiring. Not only would customers be confused, but the owners would as well. They would not know which items are in stock, need to be ordered, pending, or discontinued. The unreliable nature of the inventory would frustrate everyone and incite hoarding, and steeling from neighbouring stores.

Efficient hospital supply rooms are important as their inventory & their supply chain managment comprise a significant percentage of the hospital’s budget (I’ve seen up to 1/3). Supply rooms play a central part in the the day to day workflow of hospital staff; improving their efficiency can improve the entire hospital’s operations. Currently I spend a fair bit of time standing around looking for items that don’t exist, or steeling understocked supplies from the adjacent ward’s supply rooms (sorry).

In this article, I hope to explain the current stocking system of “par levels”, and draw your attention to the preferred industrial manufacturing system of two-bin kanban.

The Current System: 'PAR Levels'

How PAR Levels Work

Many hospitals mange stock using the PAR System (Periodic Automatic Replenishment). Each item has a set ‘par level’. This is the desired number of items the cart should stock. (I've also seen par referred to as the 'minimum number of items'). Supply managers conduct sweeps where they count the number of items remaining. The difference between the actual level and ideal PAR level indicate the number of items that need to be ordered and refilled.

PAR systems make sense if the total number of each item is always known. For instance, stores record each item that enters and leaves; creating a continuously up-to-date inventory.

However, in order to know the current inventory of a hospital, a supply stockers must go through and count every item..

To do this the supply stockers goes to each supply room and scans a barcode on a product’s shelf with a handled device. The current count of that item is entered. If it is out of stock, the count is zero. Seasoned supply stockers s are able to visually estimate, rather than manually count each item. However, this still requires a visual inspection of every item in the entire hospital, every time. Central supply then sends the number of items required to each supply room to fill the stock deficit. Depending on the department, supply counts and restocking may be taken a few times a day or every few days.

Disadvantages of PAR Levels

In hospital settings the PAR system is imperfect. It is highly labour intensive. Also, visually guessing the counts is inaccurate and makes it difficult to generate an accurate model of product flow in the hospital. This leads to stockouts or overstocking.

When products are out of stock one has to either steel from other units- which creates problems balancing the unit’s expenses and forecasting predictable use patters. Alternatively, manual requisitions must be sent to central supply. This is time intensive - the clinician must request the item, clerks coordinate processing the request, and central supply must make a delivery of a single item outside of the scheduled sweep times.

Many supply rooms do not even use a PAR system. Inventory is ordered at the discretion of the unit manager, or delivered when central supply gets a surplus.

Overall, all these systems lead to wide fluctuations between stockout and overstocking.

Proposed System: Two-Bin Kanban

Although PAR Levels are used widely throughout healthcare, they are not used in many manufacturing industries. Manufacturing has chosen systems that favour tighter supply chain control and that are far less labour intensive. Kanban is widely used. Meaning ‘signalling’, Kanban generates a ‘signal’ to trigger the next action. In this way Kanban is known as a ‘pull’ system, as downstream items are requested when upstream processes need them.

Different ‘signalling’ system exist. For instance when supply is a low, a visual card may be placed at a central ‘post’ to alert someone to to replenish the stock.

In a two-bin Kanban an empty bin triggers its re-stocking. While the first bin is re-stocked a second identical bin is used. The combined volume of the two bins is calculated to ensure there are not stockouts between cycles and that there is enough surplus for higher use. Bins are often stacked front-to-back in the shelf. Items are picked from the first 'primary' bin. When the last item is removed, the empty bin is placed on the top shelf. The second bin is pulled forward and used. Supply room managers sweep the supply rooms at fixed intervals. They remove the empty bins on the top shelf and take them back to central supply to refill. The refilled bins are placed where the second bin originally was.

ADVANTAGES OF KANBAN

There are multiple advantages of a two-bin kanban system.

Prevent stokouts & reduce requests for out-of-stock items

St Clair hospital had zero stock outs and zero manual requisitions after they initially switched to two-bin Kanban. This is possible as two-bin kanban is not simply a restocking protocol, but an inventory managment system - it actively generates data about supply usage. This data can be used to build accurate models to determine the ideal bin size and stocking frequency to reduce stockouts and minimize idle inventory.

St Clair hospital stockouts after two-bin kanban implimentation

Quicker restocking

Unlike the PAR system which requires counting of every item. Two-Bin Kanban essentially requires no counting. Each returned bin automatically triggers a count of 0. The counts can be entered manually by scanning each bin. A faster method is having the bins pass over an RFID scanner that registers each bin count as 0.

Each time a bin is re-stocked is it stocked to the same level. This optimized the re-stocking processes as it creates standardized workflow. In addition, the original container on the supply room shelf, can be refilled directly in central supply. This reduces the intermediary step of placing items from central supply, into a temporary bin before they are moved to the self in the supply rooms.

Reduce time to find items

Kanban is popular because it leads to greater satisfaction among staff. This comes from reduced time to find items. The reason for this is multifactorial. including better labeling than traditional supply rooms.

Bellevue Medical Centre & Cardinal Health cited 48% less time for clinicians to obtain supplies, and 87% less time in the supply room.

Reduce idle inventory & increase inventory selection

As the turnover of supply is closely monitored, those items that are not used can be removed. Removing idle inventory creates space for more useful items. Bellevue had a 61% reduction in inventory.

Reduces expiration of items

Supply is rotated in bins via a process of ‘first-in, first-out’. This way each bin is emptied before the second one is used. There is no risk that small items remain in the bottom of a bin unused.

Tips for Managing Kanban Supply Rooms

Training staff

Ensuring staff know (1) to only pick from the primary bin, (2) to not consolidate supply from the fist bin to the second - only change bins once empty (3) after picking the last item from a bind, to place the empty bin on the top shelf. Training videos located at the end of the article.

Bin arrangment

Traditionally bins are placed end on end, front-to-back. The advantage of this system is it leaves only one bin face to pick from. The second bin is more difficult to reach, and this discourages people from taking from the second bin. Front-to-back arrangement only works when there is space to do this. Long items, short shelf space, or oddly shaped items may not fit in this system.

Alternative ways to arrange the two bins is stacking on top of each other. They can also be placed side-by-side. When using side-by-side or on-top it is important to have an indicator to show which bin to pick from. In the image below the indicator is red/green coloring. (The problem with this system is it is not designed for the 8% of males that are color blind)

Stacked two-bin kanban

Side-by-Side two-bin kanban

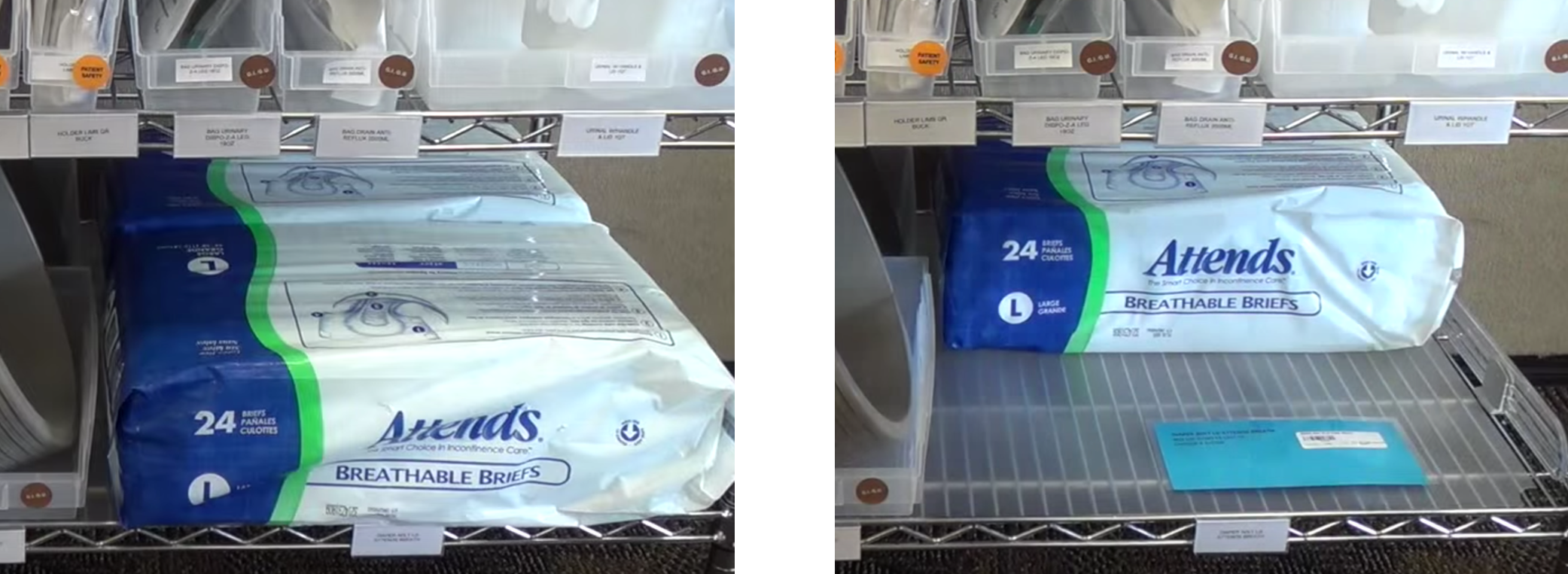

Oversized items

Can be placed on shelf with a restock card underneath them.

Item return bin

Many staff don’t know what to do with extra items. They may be replaced in the wrong self, left in the patient’s room, or thrown out. A conveniently placed ‘return item bin’ makes it obvious where unused supply goes.

Inventory guide

Each rooms should have an alphabetical list of all the items inside it. The list is indexed to each item’s location. This can be identified based on CART (A,B,C, etc), SHELF (1,2,3), BIN, (1,2,3,)

The inventory guide can be written such that the same item is listed using all the different terms that may be used to identify it.

Use further supply rooms

Infrequently used items can be stored in further supply rooms. Items in the further supply room can be listed on the inventory guide of the first supply room.

Mirror supply rooms / carts

If it is not possible to have two bins on a cart. Two carts that care close by each other can be mirrored. This way when product runs out on one cart, the other can be used while the first is re-stocked.

This can also be used for supply room that have a low inventory of large, low turnover, or expensive items. In this case, the out of supply item has in its place a card that directs one to the other supply room.

Item request process

It should be easy to request items to be considered for the supply room. Ideally one could send the name or a photo of the item one would like to a central number along with the stockroom location. This would start a process to consider that item for the stockroom.

Flexible shelving

Flexibility is important in supply room design. Too often the room is designed to maximum capacity at the start, and this prevents adjustments as new supply is introduced. Wire shelves are cheap and easily to adjust.

Shelf labels

Most systems I have seen use tags attached to the front shelf. These are annoying as they are prone to sliding, flipping upright, and generally do not look uniform.

Travis Bell & Pasqua Hospital has come up with an innovative solution using house siding clipped onto the edge of a wire shelf. This creates a smooth surface to apply stickers. There was also difficulty affixing labels to the bins. Learn more from Travis Bell about Pasqua Hospital ED: youtube video cued to 7:26min. Alternatively, clear edging used.

Tags: slide, rotate, uneven, and get in way

House siding as label: works well, looks great

Bin colors

I am not really a fan of color coded stockroom bins. Different systems exist (Red - blood/circulatory, Blue -respiratory, Green - patient care, White - dressings, Black - other.) It is easy to place a color tab at the top of a shelving unit, rather than have each bin on that shelf colored the same way. Generally, I favour clear bins as it makes it easiest to see what is inside each container, and in particular because it looks cleaner.

Constant analysis & reassessment

Every time a bin is scanned in central supply it is scanned as empty. This generates accurate data about the turnover of products. Commercial software exists that can study this data to help supply managers determine the optimal size of each in in the supply room and frequency of sweeps to refill the supply room.

DISADVANTAGES OF TWO-BIN KANBAN

Two-Bin kanban systems may not fit well on small supply carts with drawers. In these cases it may not be necessary to have a kanban system on them, and instead fill the carts to capacity at regular intervals. The intermediate supply room that is used to fill the supply carts can use two-bin kanban as a way to determine inventory flow.

A problem sometimes encountered is that the central supply room may not have enough space to sort and fill that many empty containers. Alternative systems that get around this include Kanban systems where a tag is removed from the bin. The tag could be RFID, and be placed on a board to alert central supply of the need to re-stock. This can be seen in the OR example of side-by-side bins above. Other ways to do this is with a long bin that has a stock divider in it, or with a two-sided indicator bin which is rotated to signal low supply.

See video with alternative to two-bin kanbans at with John Black and Associates.

Learn more about kanban systems in hospitals

Creating a Kanban

Collated collection of calculations, link

Video by John Black & Associates on building a kanban cart

Article on PAR Replenishment

by jump technologist, link

Thesis Paper: Benefits of a hospital two-bin kanban system

by Andrew S. Olson, September 2014. link

68 page academic paper for the Naval Postgraduate School

Case Study: Saint Alphonsus Health System

By Tony Swart, link

Logi-d

Provide software & RFID tracking products for both kanban card boards as well as implementing RFIDs in two-bin kanbans. Brochures here. Their youtube page also has videos on system in action.

Videos

Summary Video: How St Clair moved from PAR system to Kanban

Behind the scenes lessons from kanban implementation (**high yield**)

Travis Bell of Regina Qu'Appelle Health Region's Pasqua Hospital ED

Two-bin kanban without bins (eg fixed shelving). Useful in ORs

Brant Community Healthcare System.

Scarborough Hospital

Nursing training video on how to use a two-bin kanban system

Cardinal Health Project Video